TIK, which started with the production of piston since 1985. TIK Piston has the ability to provide both gasoline and diesel engines in Piston production from 40 mm to 170 mm diameter dimensions. Our cast piston feature oil cooled and ring retainers with various surface treatments from ceramic coating, head anodized to moly skirt treatment. In nowadays, TIK also have the ability to provide forged piston for racing industry.

TIK continues to believe “Your Engine is our concern” by continuously increasing its performance in the engine with its R&D studies by combining material and alloy properties, dimensional features of all pistons produced by them with its experience in the engine industry.

Casting

Our expertise in aluminum casting process can make high quality casting with complex geometry to meet critical specifications. For having SPECTRO machine, we can make sure each piston can achieve global material standards.

Heat Treatment

With proper T6 treatment, we can make sure the hardness and internal tension realeased proeperly.

TIK can also provide forged piston with either 2618 or 4032 material. For having suitable heat treatment technology, we can provide best options for racing industry with qualified piston.

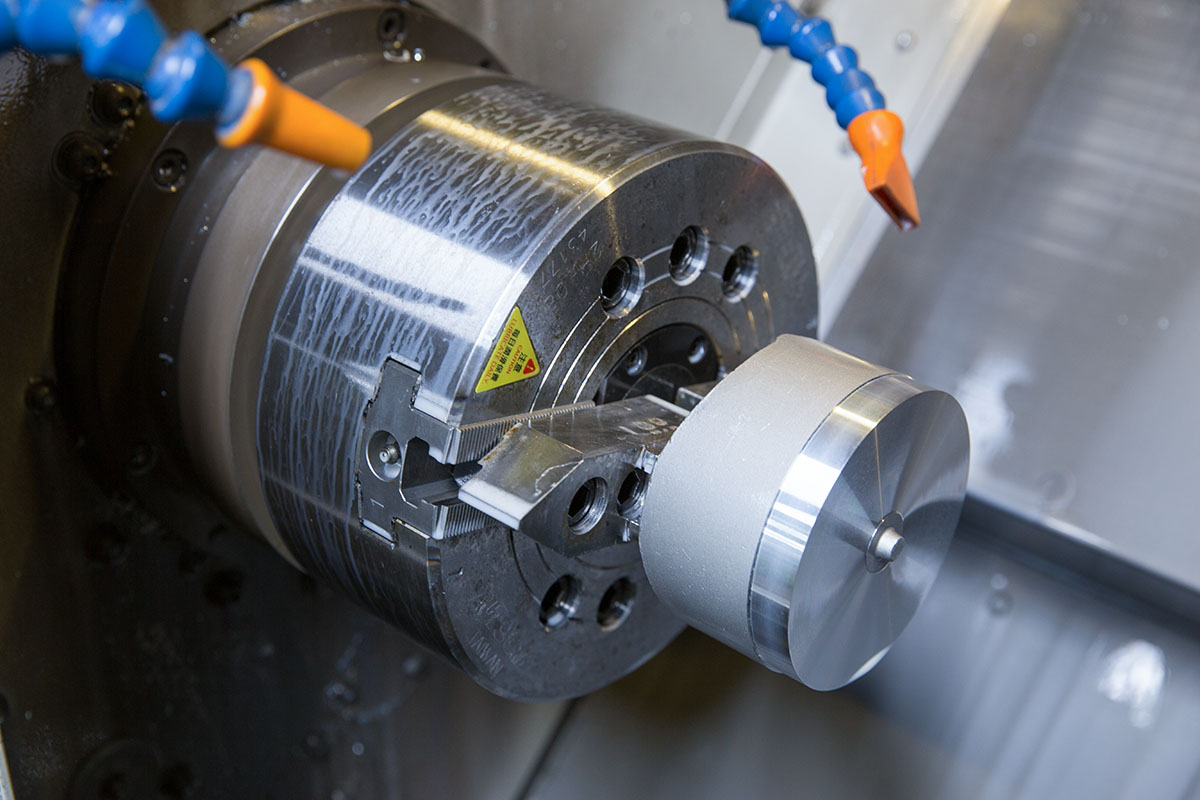

Precision Machining

Advance CNC Lathes & CNC Machine Centers brings tight tolerance to satisfy advance engine technology.

Surface Treatment

Piston surface treatments include: Ceramic coating, head anodizing moly skirt treatment.